By Lieutenant Commander Jim Halsell, U.S. Navy*

The United States will require more than its existing inventory of nuclear-powered submarines to ensure victory in a conflict with China. The Navy should augment its existing submarine force with a fleet of conventionally powered submarines capable of launching cruise missiles.

By producing smaller, more cost-efficient submarines with the help of allies, the U.S. submarine force could mitigate the relatively low number of nuclear-powered submarines available for a conflict. During peacetime, these submarines — equipped with weapons capable of eliminating enemy surface combatants and shore-based targets from their patrol areas — could be a strong deterrent. In a conflict, they would provide a powerful element of sea control and sea denial.

Mission Dictates the Weapon, Weapon Dictates the Platform

In a conflict with a modern, technologically advanced opponent such as the People’s Liberation Army Navy (PLAN), the U.S. submarine force would need to efficiently neutralize enemy surface ships capable of launching missiles that would threaten U.S. aircraft carriers and amphibious ships. This antisurface warfare (ASuW) capability currently relies on the U.S. fleet of expensive nuclear-powered fast-attack submarines (SSNs) employing Mk 48 advanced capability torpedoes. As the intelligence-gathering and ship-locating abilities of China and Russia improve, the relatively limited number of U.S. SSNs available in theater, coupled with the limited availability of torpedoes, could leave the United States disadvantaged in a conflict.

To address this challenge, the Navy must field a cost-efficient, modern submarine coupled with a potent sea-launched cruise missile capable of targeting ships and land-based assets from a distance. The Navy needs a conventionally powered cruise-missile submarine (SSG) that it can build in sufficient numbers.

In a U.S.-China conflict, the PLAN’s inventory of anti-ship cruise missiles (ASCMs) would be a critical capability with which to contend. The United States would depend heavily on submarines to conduct ASuW operations to eliminate enemy maritime platforms that carry ASCMs until additional domains could be opened for U.S. aircraft and surface assets. While several Chinese submarine classes can launch ASCMs, the lion’s share of these ship killers are carried by surface combatants such as the PLAN’s Renhai-, Luyang-, and Jiangkai-class warships. While the U.S. Mk 48 is the most capable heavyweight torpedo ever fielded by a navy, it is a close-range weapon. The effective range of a torpedo requires a submarine to get close enough to potential targets that modern warships equipped with capable sonar systems pose legitimate threats. To extend their reach, U.S. submarines need to be equipped with modern ASCMs of their own.

The Navy retired the UGM-84A undersea-launched Harpoon missile in 1997, leaving the submarine force without an antiship missile for decades. During exercise Rim of the Pacific (RimPac) 2018, the USS Olympia (SSN-717) fired a Harpoon at the ex-Racine (LST-1191), hinting at the intention to restore a submarine-launched cruise-missile capability to the fleet.1 The Navy contracted with Boeing to refurbish and recertify UGM-84 Harpoon missiles to reintroduce the capability to the Los Angeles–class submarines later the same year.2

Differences in weapon delivery systems, however, mean these torpedo tube–launched missiles are not compatible with Virginia-class submarines. Therefore, most of the SSN fleet is incapable of using the Harpoon. While the Block V Maritime Strike Tomahawk is set to be deployed on SSNs soon, testing is still underway.3 As a result, the United States has a critical gap in this area. The Navy needs a submarine-launched ASCM that is compatible with modern delivery systems such as the vertical launch system (VLS) and the Virginia payload tube (VPT).

The Case for SSGs

In the decades since World War II, the U.S. submarine force has shifted away from high-volume, diesel “fleet boats” and now consists solely of high-end, multi-mission-capable nuclear-powered submarines. The problem with the makeup of today’s submarine force is that these deep-diving, fast-driving, nuclear-powered submarines are expensive. These ships are both too expensive to build in sufficient quantity to meet operational requirements and too costly, in terms of dollars and capabilities, to risk losing in combat.

The cost per hull of a new Virginia-class SSN was originally $2.8 billion, but following the incorporation of the Virginia Payload Module in the USS Arizona (SSN-803) and follow-on Block V boats, that cost now exceeds $4 billion.4 In comparison, Japan spent an estimated $536 million per hull for its Sōryū-class submarines, which feature air-independent propulsion (AIP), allowing them to operate for weeks without snorkeling.5 Japan’s newer Taigei-class submarines are being built at an even cheaper $473 million per hull.6

Meanwhile, the Republic of Korea has in recent years built three of its KSS-III–class conventionally powered submarines for roughly $845 million per hull.7 These ships are notable because they incorporate six VLS cells. While these boats are more expensive than the Taigei or Sōryū classes, the cost per hull likely could be driven down further if they were built in the volume the United States would demand. If the United States were able to produce similarly capable ships at a comparable cost, it could purchase five SSGs for the cost of each new Virginia-class ship.

Much of the disparity stems from the prohibitive cost of nuclear propulsion systems. Conventional submarines are cheaper not only to build, but also to maintain, benefiting from simpler refueling logistics and a dramatically lower cost threshold. A 2012 Congressional Budget Office study concluded nuclear power is economical only if oil exceeds $223 per barrel (about $305 in 2024), far above current prices ($78 in 2024).8 Further, the logistics network required to refuel diesel-electric submarines already exists in the system that supports the Navy’s forward-deployed surface assets.

If each U.S. SSG hull were equipped with 14 ASCMs via either VLS cells or two of the seven-missile-capacity VPTs, five boats would carry 70 ASCMs. For the same cost, one Block V Virginia-class SSN with six VPTs will carry only 42 ASCMs. More important, by distributing the offensive power of these 70 ASCMs across multiple submarines, they can be employed in dispersed positions across the theater, enhancing targeting options and reducing the capability cost of losing one in combat. In addition, by incorporating the VPTs into the SSG design, these launch platforms would be future-proofed, capable of integrating emerging missile technologies as they are developed.

Another factor that drives up the cost of SSNs is that these highly capable submarines are employed across such a wide range of missions. Because of this, they must be designed to meet a multitude of specifications, and their crews must spend time training to fulfill the breadth of their capabilities. In many respects, SSNs are too important to risk losing in combat. Engineering a nonnuclear class with a narrow mission focus and lower per-unit cost would mitigate the strategic risk of losing a submarine in combat. SSGs also would reduce the mission burden placed on today’s SSN fleet, allowing an already limited asset to concentrate on the high-end missions it would have to fulfill, i.e., hunting the adversary’s submarines.

SSGs would be designed from the engineering and construction phase through the training and operations phase with only specific missions in mind. Since crew sizes would be much smaller than on existing SSNs, and engineering personnel would require less specialized training, operating costs would be greatly reduced. With a primary focus on launching land-attack and ASuW cruise missiles, SSGs could hone their craft and maintain readiness specifically to fight enemy surface ships.

Operational Tradeoffs of Conventional Submarines

One of the disadvantages associated with conventionally powered submarines is the operational limitations these ships face when compared with nuclear-powered units. While SSGs would certainly have a lower top speed, shorter range, and limited endurance compared to SSNs, many of these limitations could be compensated for by forward basing.

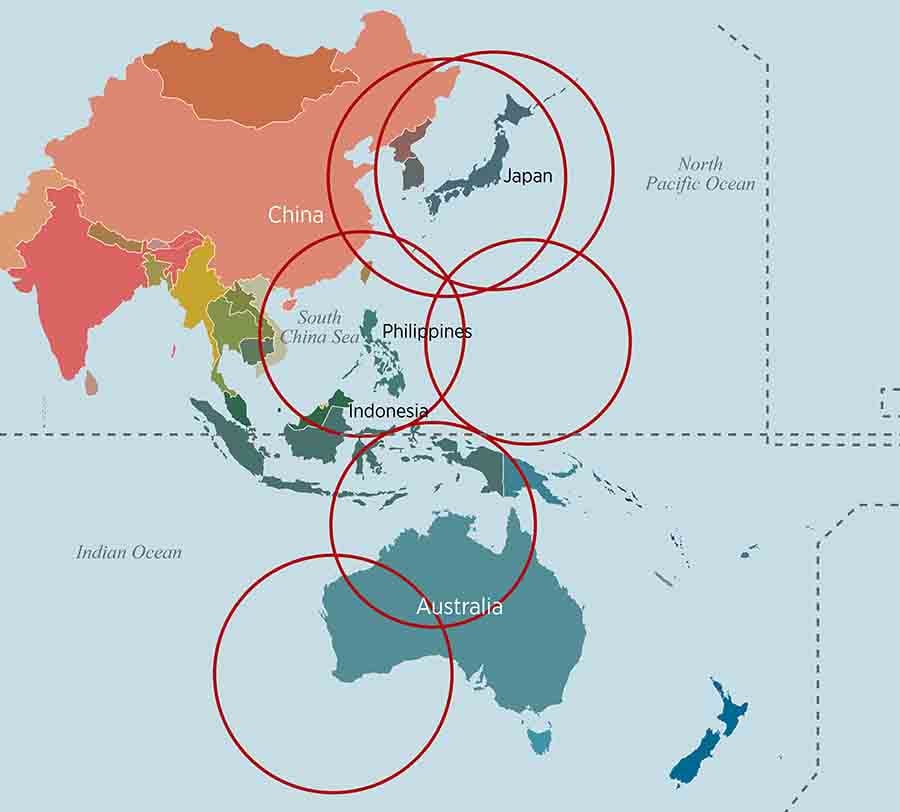

Several suitable locations already exist in the Indo-Pacific, while other potential homeports could quickly be developed. (See Figure 1.) In Japan, the U.S. Navy already bases ships in Sasebo and Yokosuka. A third potential submarine homeport, which the Japan Maritime Self-Defense Force already uses for its Sōryūand Taigei classes, exists at Kure Naval Base. The U.S. naval base in Guam also could provide a suitable homeport.

Meanwhile, in Australia, the Royal Australian Navy homeports its Collins-class SSGs at HMAS Stirling, near Perth. While this facility already supports submarines, a more suitable location to base U.S. SSGs given on geographic considerations might be northern Australia. In addition, with the renewed interest in expanding security cooperation with the Philippines, a homeport could be established at the former U.S. base at Subic Bay, bordering the South China Sea. Taking into consideration the 900 nautical mile range of the existing maritime Tomahawk weapon systems, all these homeport choices would put a U.S. SSG within striking distance of PLAN operating areas.9 The infrastructure required to host these submarines likely could be developed at a relatively low cost because facilities for special maintenance needs—such as those associated with nuclear-powered submarines—would not be required.

The limitations of nonnuclear-powered submarines could be further mitigated by incorporating air-independent propulsion (AIP) and/or advanced battery technologies into their design, reducing the need for regular operation of a noisy diesel engine, also known as “snorkeling.” For its last two ships of the Sōryū class and the entire three-ship run of the Taigei class to date, Japan has begun using advanced lithium-ion batteries in place of the AIP systems used on previous Sōryūhulls.10 This made Japan the first known country to have fitted this technology into a submarine, although the Republic of Korea’s KSS-III class now boasts lithium-ion batteries as well.

Allied Collaboration

One of the most compelling opportunities presented by the development of a U.S. conventionally powered submarine would be the chance to design and build it in partnership with key Indo-Pacific allies. Japan, South Korea, and Australia have decades of experience operating and constructing nonnuclear-powered submarines, and they are getting better with each iteration. Japan’s Taigei-class submarines and Korea’s KSS-III class incorporate VLS and AIP technology, making them ideal platforms to draw from in a collaborative design process.11 Australia has a wealth of knowledge and experience operating conventionally powered submarines and already uses the U.S.-made BYG-1 combat control system and Mk 48 torpedo. Collaborating with one or more of these countries would allow the United States to compress the design-to-commissioning timeline, tap into existing technical expertise, and share development costs.

Collaboration also would support deeper operational integration. A jointly developed SSG, based on the modular design philosophies used in Korea’s KSS-III and tailored for compatibility with the BYG-1 combat control system, could be manufactured in parallel across multiple shipyards in the United States and in allied nations with additional shipyard capacity, increasing production speed without overwhelming the overstretched U.S. submarine industrial base. Under AUKUS Pillar II, this kind of cooperative development aligns with stated goals of integrating advanced capabilities and sharing platform development among trusted partners.12 Further, with Japan and Korea both facing similar strategic threats and demographic-industrial challenges, a multilateral production model could generate efficiencies in workforce training, component standardization, and even base infrastructure.

Such an arrangement also would lessen the burden on the already-stretched U.S. shipbuilding base, while creating political alignment and a shared strategic stake in the deployment of these boats. South Korea’s shipyards, DSME/Hanwha Ocean and Hyundai Heavy Industries, which produce the KSS-III Block II boats, and Japan’s builders Mitsubishi Heavy Industries and Kawasaki Heavy Industries are capable of high-precision construction at scale. A codesigned U.S.-allied SSG not only would reduce the timeline to field these units, but also would cement alliance ties through shared industrial base integration and doctrinal development. In short, building submarines together is not just cost-effective, it is alliance-forging.

Now is the Time

The recent executive order on revitalizing the maritime industrial base offers a unique policy window for action. Its core objectives of restoring shipbuilding capacity, strengthening allied investment in U.S. maritime production, and leveraging tools such as the Defense Production Act and Maritime Prosperity Zones align with the goals of a conventionally powered U.S. submarine program.13

Section 4 of the executive order calls for investing in both commercial and defense shipbuilding capabilities, explicitly including component supply chains and repair infrastructure. A conventional submarine line would fulfill these criteria while simultaneously providing sustained employment for skilled trades and engineers, many of whom might otherwise be lost to attrition in the absence of near-term submarine work.

Section 8 encourages partnerships with allies to facilitate foreign capital investment in the U.S. shipbuilding base. This provides a legal and political framework to support trilateral or quadrilateral submarine development efforts with Korea, Japan, and Australia. A jointly developed conventional SSG, partially built in U.S. yards, could become a flagship program under the Maritime Action Plan and a symbol of allied maritime solidarity in the Indo-Pacific.

Section 13’s focus on expanding mariner and shipbuilder training through new merchant marine academies, credentialing reform, and international faculty exchanges also supports the human capital side of such a project. A U.S.-led conventional submarine program could become the centerpiece of a revitalized maritime workforce pipeline.

Finally, by linking this effort to the broader shipbuilding recovery envisioned in Sections 5, 10, and 19, the program not only would stand on its strategic and operational merits, but also would be a bipartisan mechanism for economic renewal, industrial resilience, and allied integration in a contested maritime century.

The combination of capable antiship and land-attack cruise missiles and a fleet of small, relatively inexpensive conventional submarines, built jointly with allies, would make for a formidable asset in a future conflict. The Navy’s next undersea platform should not be a dream of the distant future. It should be a practical, allied-built, and mission-driven asset, designed for the challenges of the Indo-Pacific and built for the fight the Navy might face in the next decade.

*Lieutenant Commander Halsell is a submarine warfare officer. His most recent assignment at sea was engineer officer on board the USS Topeka (SSN-754). He is a PhD student at Johns Hopkins School of Advanced International Studies, researching the potential effect of deep-seabed mining on Chinese maritime sovereignty assertions.

1. Joseph Trevithick, “U.S. Navy Sub to Fire Harpoon Anti-Ship Missile Years After They Left the Force,” The Drive, 27 July 2018.

2. Sydney J. Freedberg Jr., “Navy to Begin Arming Subs with Ship-Killer Missile,” Breaking Defense, 18 December 2018.

3. Sam LaGrone, “U.S. Navy Anti-Ship Tomahawk Set for Surface Ships, Subs Starting in 2021,” USNI News, 18 February 2016.

4. Ronald O’Rourke, Navy Virginia-Class Submarine Program and

AUKUS Submarine (Pillar 1) Project: Background and Issues for Congress (Washington, DC: Congressional Research Service, 28 March 2025).

5. Ministry of Defense (Japan), “Budget,” 4 March 2016.

6. Kosuke Takahashi, “Japan Commissions Third Taigei-Class Submarine,” Naval News, 8 March 2024.

7. Xavier Vavasseur, “South Korea’s DSME Wins Contract for 2nd KSS-III Batch-II Submarine,” Naval News, 10 September 2021.

8. Douglas W. Elmendorf, The Cost-Effectiveness of Nuclear Power for Navy Surface Ships (Washington, DC: Congressional Budget Office, March 2011).

9. CSIS Missile Defense Project, “Tomahawk,” Missile Threat, 15 June 2018.

10. Kyle Mizokami, “Introducing Japan’s Lithium Ion Battery-Powered Submarine,” Popular Mechanics, 14 November 2019.

11. LT (j.g.) Jeong Soo Kim, USN, “Use Allies in Shipyard Modernization,” U.S. Naval Institute Proceedings 149, no. 5 (May 2023).

12. Indo-Pacific Command, “AUKUS Agreement for Cooperation Related to Naval Nuclear Propulsion,” ASA Media, 15 August 2024.

13. President Donald J. Trump, “Executive Order on Revitalizing the Maritime Industrial Base to Strengthen National Security and Economic Prosperity,” The White House, 9 April 2025.

I believe you may be on the money. Will certainly have more platforms in the water in a quicker timeframe. Capacity to build is the major constraint in US. Our allies in JAP/KOR certainly know how to build quality in a timely and cost efficient manner. For an operational basing solution, may I suggest http://www.gascoynegateway.com.au